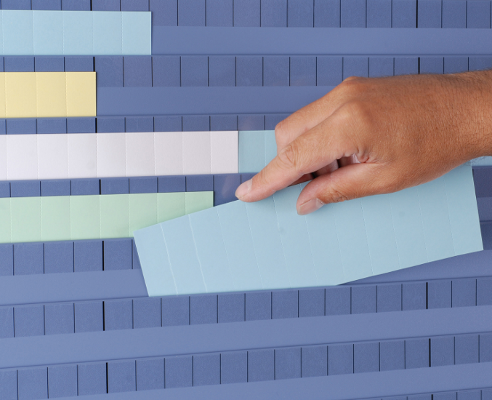

The Card Kanban Method

Have you read Eurocharts Blog on Understanding Card Kanban?

Lean Production – Card Kanban

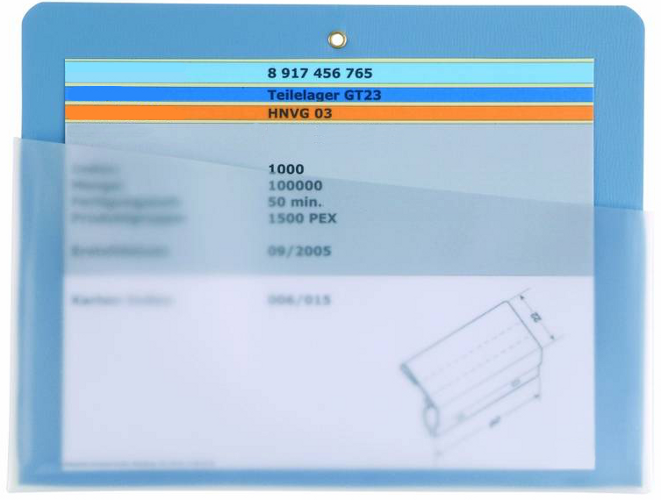

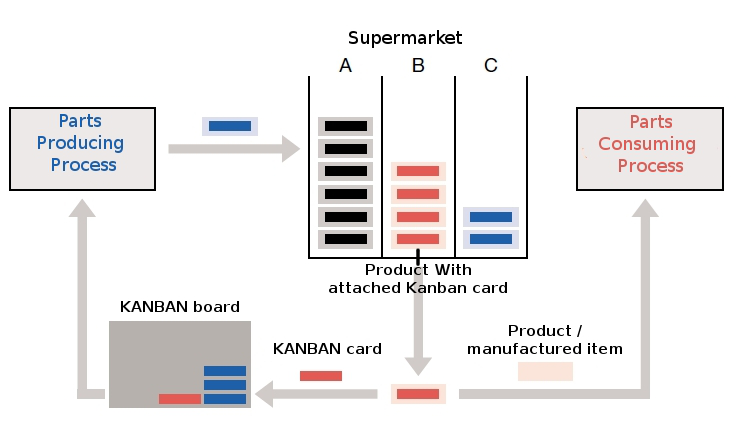

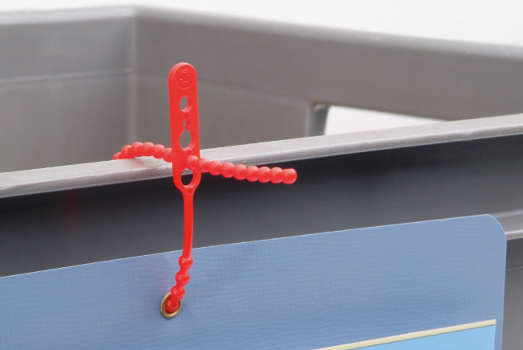

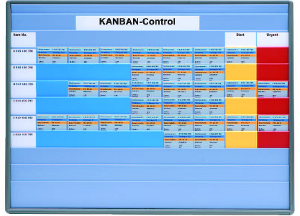

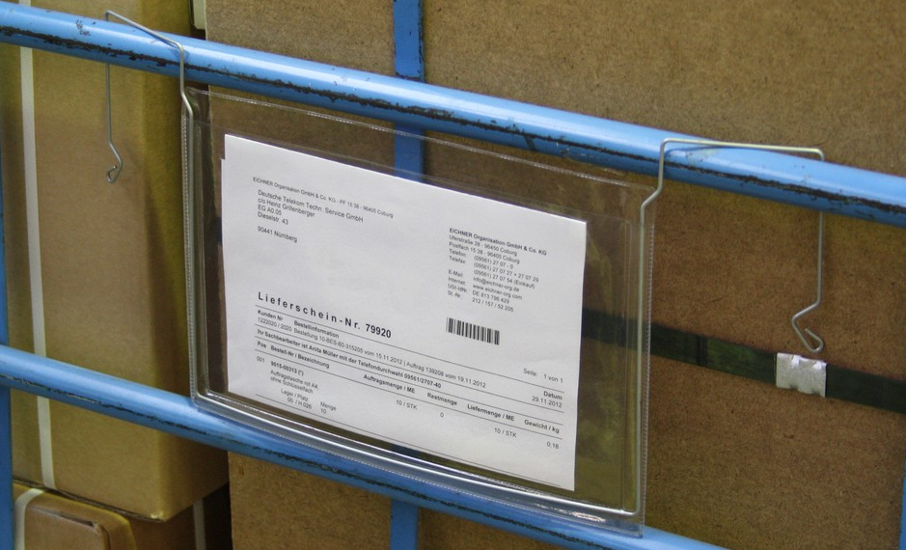

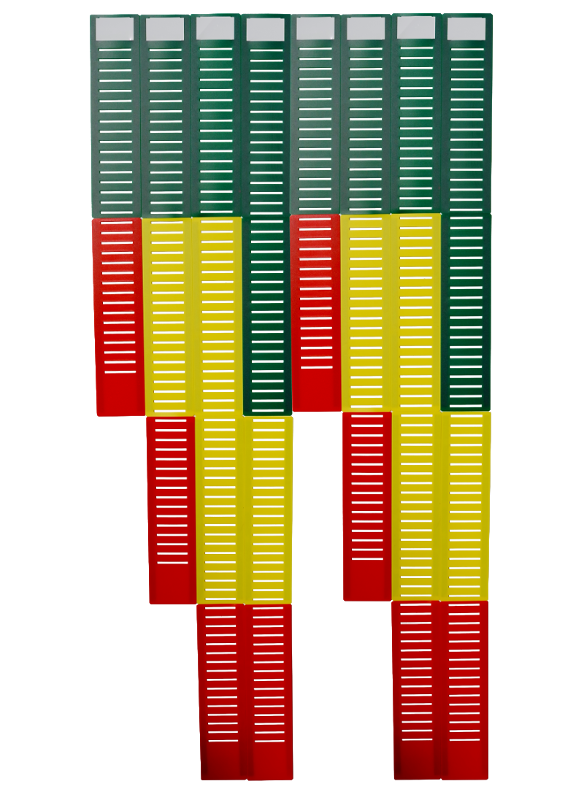

Kanban is a model of economic production management used by a great number of well known companies all over the world. Its basic principles were developed by the Toyota group in Japan, with the term “KANBAN” being literally translated as a visual card or signal. The core notion of lean production is the design of a value added process as a continuous flow.